Have you ever wondered about the precise differences between procurement and supply chain management? While often used interchangeably, these terms represent distinct yet interconnected functions critical to the success of any business, especially within a dynamic market like Pakistan. Understanding their nuances is key to optimizing operations and achieving strategic goals. This article will demystify both procurement and supply chain management, exploring each concept in detail and highlighting their crucial relationship.

Procurement: The Strategic Beginning of Acquisition

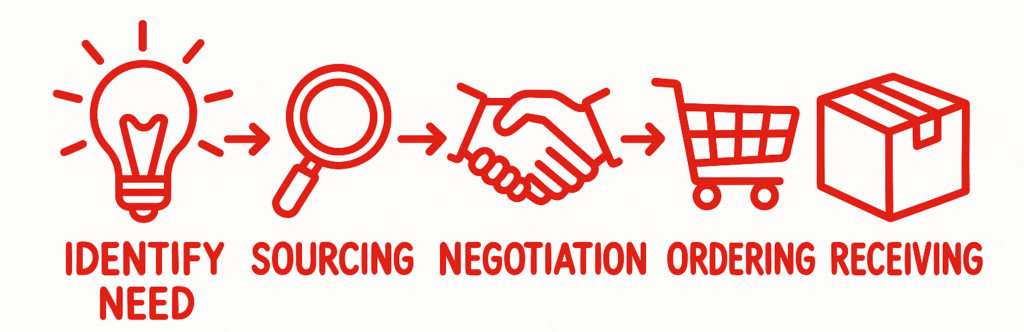

At its core, procurement is the overarching strategic function of obtaining all the tangible goods, intangible services, and works a company needs to operate. It’s far more than simple buying; it’s a high-level skill. The procurement process initiates by identifying a specific organizational need and is considered complete only when the goods or services fulfilling that need are successfully delivered.

Think of procurement as the meticulous planning and execution involved in acquiring essential resources. Its scope is broad, encompassing various strategic elements vital to effective procurement and supply chain operations:

- Added Value & Cost Management: Procurement’s strategic nature means focusing on securing the best overall value, not merely the lowest price. For instance, a Pakistani pharmaceutical company might prioritize investing in a higher-priced, internationally certified raw material. This guarantees superior drug efficacy and compliance, thereby adding substantial value to its final product and brand reputation.

- Inventory Management: This involves overseeing components, raw materials, work-in-progress, and finished goods. It also includes managing relationships with suppliers required for creating goods and services for the customer. Inventory can also refer to the units or value of stock a company holds. For a large-scale agricultural business in Punjab, effective procurement ensures timely access to seeds, fertilizers, and machinery, directly impacting crop yields and market supply.

- Logistics Coordination in Procurement: While often seen as a broader supply chain function, procurement directly impacts logistics. This happens by determining delivery terms, transportation modes, and supplier locations. Procuring specialized textile machinery from Germany for a factory in Faisalabad, for example, necessitates a robust logistical plan from the initial procurement phase, including freight forwarding and customs clearance.

- Purchasing: This is the specific, transactional act of physically ordering and buying something. It’s a critical, yet contained, operational function within the broader procurement process.

- Quality Assurance: Ensuring that all acquired goods and services meet predefined quality standards and specifications is a fundamental procurement responsibility.

- Supplier Relationship Management: Building and nurturing strong, long-term relationships with suppliers is paramount. This ensures consistent supply and potential for cost savings and innovation.

- Waste Management: Procurement increasingly considers the entire lifecycle of products. This includes responsible sourcing, minimizing waste generation, and managing eventual disposal and potential for recycling.

Key takeaway: While terms like “purchasing” and “supply” are frequently used interchangeably with “procurement,” they possess distinct meanings. Our sources clearly state that “Purchasing and supply are functions within the procurement process”. As a foundational principle, “Without procurement there would be no purchasing and without purchasing there would be no supply”. This emphasizes procurement’s indispensable role as the starting point for all value creation.

What is a Supply Chain? The Product’s End-to-End Journey

A supply chain is a comprehensive network encompassing all organizations and activities associated with the flow and transformation of goods. It starts from the raw materials stage and goes all the way through to the end user. This includes the crucial associated information flows. It acts as a channel for goods distribution, originating with the supplier of raw materials or components, moving through various operational processes to distributors and retailers, and ultimately delivering to the consumer.

A supply chain involves a complex network of individuals, organizations, technology, activities, and resources. All these elements collaborate to ensure that goods or services flow efficiently along the chain. These chains can vary dramatically in complexity – from a localized bakery in Gilgit-Baltistan sourcing ingredients from nearby farms to a multinational electronics company assembling smartphones in Pakistan with components from across the globe. The effectiveness of the entire chain hinges on the seamless collaboration of all its parts. If one component fails, it can lead to cascading failures further along the chain, underscoring the critical need for integration in procurement and supply chain operations.

The Three Main Industry Sectors and the Supply Chain

Supply chains inherently span across Pakistan’s diverse industry sectors:

- Primary Sector: This sector includes industries that extract natural resources directly from the earth. In Pakistan, this encompasses vital activities like cotton farming in Sindh, gas exploration in Balochistan, and large-scale fishing operations along the Arabian Sea. These are the initial nodes for many supply chains, providing foundational raw materials.

- Secondary Sector: This sector encompasses the manufacturing and construction industries, where raw materials are transformed into finished products. For example, the oil drilled by the primary sector can be refined into petrol or kerosene in Pakistani refineries. Similarly, raw materials acquired by the primary sector are assembled to build houses and critical infrastructure projects across the country.

- Tertiary Sector: Comprising service industries, this sector provides essential support for the production and distribution processes. Examples crucial to Pakistan’s supply chains include logistics and transportation companies moving goods across vast distances (e.g., from Karachi Port to upcountry distribution hubs), insurance providers mitigating risks for cargo, and banking services facilitating complex financial transactions.

All three sectors are intrinsically linked, working in concert to form the complete supply chain, with each adding significant value to the overall process. Every job role, from the farmer tending fields to the tech professional managing data networks, ultimately fits into one of these fundamental sectors.

Stages in a Supply Chain

A basic supply chain model illustrates the flow through two crucial stages:

- Upstream: This refers to the initial supply flow of raw materials, components, and parts necessary for production. For instance, this segment includes textile ginning factories receiving raw cotton from farmers and then supplying processed cotton to yarn manufacturers, or mining companies extracting minerals for industrial use.

- Downstream: This represents the segment of the supply chain that the organization feeds into. It moves from the finished product towards the end user. An example would be a food processing company in Pakistan taking manufactured ingredients, packaging them, distributing them to wholesale centers, and finally seeing them arrive at a local kiryana store for customer purchase.

https://example.com/doodle_basic_supply_chain.png” alt=”Doodle showing a basic supply chain model: Producers -> Suppliers -> Manufacturers -> Distributors -> Retailers -> Customers. Emphasizes the interconnectedness and flow in procurement and supply chain management.” width=”600″ height=”400″> (Image description: A simple doodle illustrating a basic supply chain model. It shows a sequential flow from ‘Producers’ (e.g., a farm icon) to ‘Suppliers’ (e.g., a warehouse icon) to ‘Manufacturers’ (e.g., a factory icon) to ‘Distributors’ (e.g., a truck icon) to ‘Retailers’ (e.g., a shop icon) and finally to ‘Customers’ (e.g., a person icon). Arrows connect each stage, illustrating the linear flow of goods in the context of procurement and supply chain management.)

Supply Chain Management (SCM): Orchestrating the Entire Network

For a supply chain to work effectively, it must be proactively managed. Supply Chain Management (SCM) is the strategic coordination and integration of all activities involved in the supply chain to achieve overarching goals: reducing costs, improving value, and mitigating risks. SCM aims to provide a substantial competitive advantage over competitors by adding value throughout the entire process. It ensures operations are conducted in the most effective, efficient, and ethical manner.

SCM extends beyond simply overseeing the flow of goods; it involves actively managing complex relationships across the entire network, including critical customer relationships. Key areas of focus for SCM in the context of procurement and supply chain functions include:

- Price Optimization: This involves optimizing pricing strategies and total cost of ownership across all tiers of the supply chain to ensure competitiveness.

- Delivery Efficiency: Ensuring timely, reliable, and efficient delivery of goods and services to meet customer demand and minimize disruptions.

- Strategic Storage: This includes strategically managing inventory levels and warehousing operations to minimize holding costs, prevent obsolescence, and ensure product availability.

- Ethical Practices: Upholding strong ethical principles that govern the behavior of all parties within the supply chain is critical. This ensures the supply chain remains free from modern slavery, child labor, poor working conditions, unacceptable pay, and all other forms of unethical behavior. For example, a major Pakistani food conglomerate would implement stringent SCM policies to ensure fair labor practices among its agricultural suppliers, addressing social responsibility.

- Environment & Sustainability: This involves implementing sustainable practices to minimize environmental impact (e.g., reducing carbon footprint in logistics, promoting eco-friendly packaging) and promoting long-term ecological and social well-being throughout the chain.

- Effective Communication: Fostering clear, transparent, and especially bidirectional communication among all stakeholders in the supply chain is vital for quick decision-making and problem-solving.

- Quality Consistency: Maintaining consistent quality standards throughout the entire product journey, from the sourcing of raw materials to the final delivery to the end consumer. All parties within the supply chain should work to the same standards.

The ramifications of poorly managed SCM can be severe. If consumers discover that any part of an organization’s supply chain is not managed correctly or engages in unacceptable practices, the organization could suffer massive reputational damage. This impacts consumer trust and market share. This highlights why many organizations, particularly those with a strong global brand presence and commitment to corporate social responsibility in Pakistan, insist that all parties within their chain adhere to stringent standards, legislation, and regulations. Less stringent approaches can lead to negative publicity and damage organizational success.

Supply Chain Networks (SCN)

A supply chain network (SCN) is an evolution of the basic supply chain. It represents a more complex structure with a higher level of interdependence and connectivity. It facilitates a two-way exchange of information and materials to successfully meet customer demands between numerous organizations, both upstream and downstream. Individual supply chains are effectively components within these larger, more intricate networks.

A supply chain network is typically designed around five key functional areas, extending beyond the direct flow of goods:

- External Suppliers: These are the entities who provide the materials to make the goods or services.

- Manufacturers: These are the organizations responsible for producing the end product.

- Distribution/Wholesale Centers: These facilities manage the storage and transportation of the products.

- Logistics Providers: These entities ensure that everything is where it should be at the required time. In Pakistan, this could include third-party logistics (3PL) companies managing transportation fleets and warehouses.

- Customers: The ultimate recipients, whose demands and feedback drive the entire network.

Within supply chain networks, physical flows (the movement and storage of materials and end products) are generally one-way, from supplier to consumer. However, information flows two ways, enabling crucial feedback loops and responsive adjustments throughout the network. This bidirectional information flow is a defining characteristic of an SCN and is vital for its adaptability and success.

Remember: In a supply chain network, goods flow one way, whereas information flows two ways.

The Core Difference Summarized: Procurement and Supply Chain Management

| Feature | Procurement | Supply Chain Management |

| Scope | Strategic acquisition of goods, services, and works needed for internal operations. | Overall strategic management and orchestration of the entire supply chain network, from initial procurement through to final customer delivery. |

| Focus | Specific transactions; obtaining the right resources at the right value for immediate and near-term needs. | Holistic view; optimizing the entire integrated flow of products, information, and finances across all partners for long-term efficiency, value, and resilience. |

| Primary Goal | Secure necessary inputs efficiently and cost-effectively. | Reduce overall costs, improve delivered value, and reduce risk across the entire network. |

| Relationship to Other | A critical, foundational function within supply chain management. | Encompasses procurement and integrates it with manufacturing, logistics, distribution, and customer relationship management. |

| Direction of Flow (Goods/Info) | Primarily focused on inbound flow of goods and services with associated information. | Manages both upstream (inbound) and downstream (outbound) physical flows, with vital two-way information flow throughout the network. |

For a more detailed understanding of procurement strategies, visit our Templates Section to explore comprehensive resources and insights tailored to optimizing procurement within Pakistan’s economic landscape.