In the intricate world of business operations, particularly within the dynamic Pakistani market, two terms often used interchangeably, yet distinct in their scope, are Procurement vs. Supply Chain. While undoubtedly interlinked and crucial for any organization’s success, understanding their individual roles and functions is paramount. At ProcureXpert, we believe in shedding light on these fundamental concepts to empower your procurement strategies and optimize your entire supply chain.

Are Procurement vs. Supply Chain the Same? Unraveling the Connection

Let’s start by clarifying a common misconception: supply chain management and procurement are not identical. Think of it this way: without effective procurement, a supply chain simply wouldn’t exist. Procurement acts as the foundational step, the initial spark that ignites the entire process of getting goods and services into an organization. It’s about meticulously obtaining the necessary products and services to fulfill a specific need. On the other hand, the supply chain encompasses the broader infrastructure and processes involved in the physical delivery of those products and services, stretching from the very first supplier to the final consumer. This comparison of Procurement vs. Supply Chain is vital for local businesses.

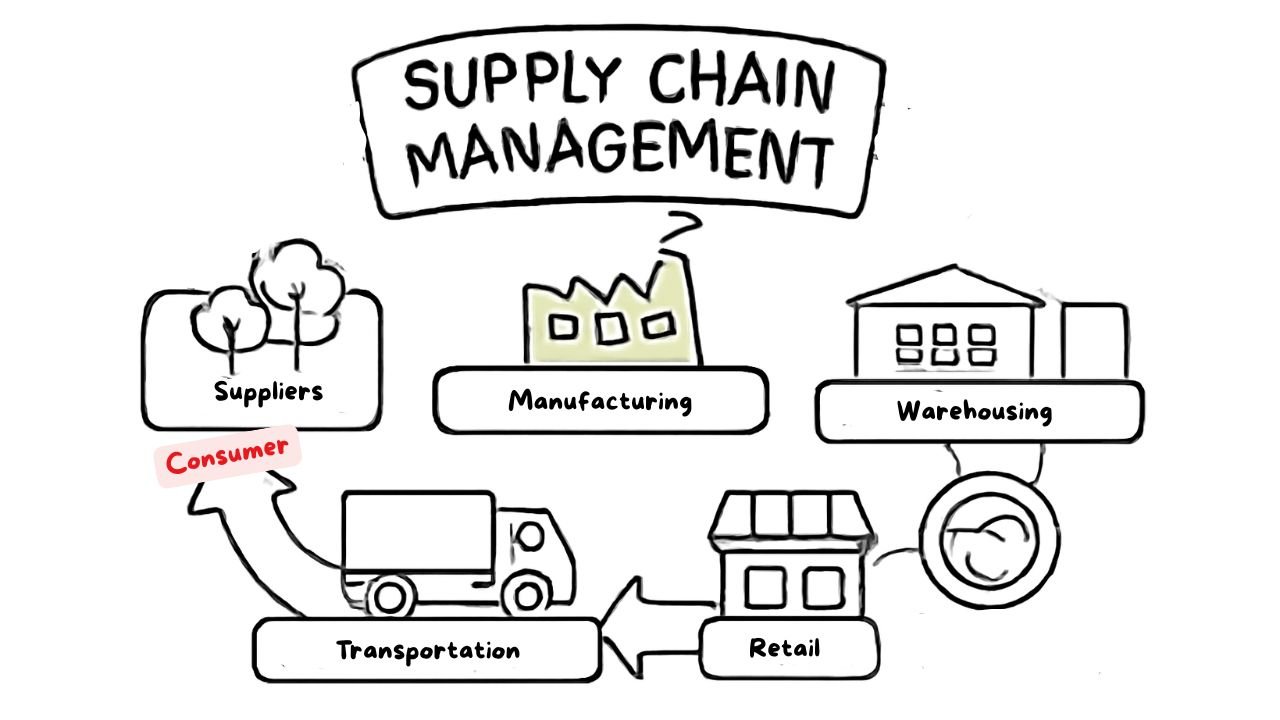

Imagine a local textile manufacturer in Faisalabad. Their procurement team is responsible for sourcing high-quality cotton, dyes, and machinery parts. This involves identifying reliable suppliers, negotiating prices, ensuring quality standards, and managing the delivery of these raw materials. Without this initial procurement effort, the factory would have no inputs to begin production. The supply chain, however, extends beyond this. It includes the transportation of the raw cotton from a ginning factory in Rahim Yar Khan, the manufacturing process in Faisalabad, the warehousing of finished fabrics, and finally, the distribution of those fabrics to retailers in Lahore, Karachi, and even international markets. This holistic view is central to effective Procurement vs. Supply Chain operations in Pakistan.

The Pillars of Procurement: A Closer Look

Procurement is a multi-faceted discipline involving several critical activities. These include:

- Preparing Specifications: Before any purchase can be made, a clear and detailed understanding of what is needed is essential. For a construction company in Islamabad building a new housing society, this could involve drafting precise specifications for cement, steel, plumbing fixtures, and electrical wiring, ensuring they meet national building codes and project requirements. This initial step is a core aspect of Procurement vs. Supply Chain.

- Sourcing Buying: This is where the hunt for the right suppliers begins. It involves market research, evaluating potential vendors, requesting bids, negotiating contracts, and ultimately making the purchase. Consider a restaurant chain in Karachi sourcing fresh produce. Their procurement team would identify local farms, assess their capacity and quality, and then enter into agreements for regular supply.

- Monitoring Quality: It’s not enough to just buy; ensuring the procured goods and services meet the required quality standards is crucial. For a pharmaceutical company in Lahore, this means rigorously testing raw materials and packaging to comply with drug regulatory authority standards, preventing costly recalls and safeguarding public health.

- Stock control: Managing inventory effectively is a key part of procurement to avoid overstocking or stockouts. A large electronics retailer in Pakistan needs robust stock control systems to manage the thousands of different products they carry, from mobile phones to washing machines, ensuring popular items are always available while minimizing holding costs for slower-moving inventory.

- Disposal of waste: The procurement cycle also extends to the responsible disposal of waste generated from operations or obsolete materials. A manufacturing plant in Sialkot, producing surgical instruments, would need a procurement strategy for disposing of metal scraps and chemical by-products in an environmentally sound manner, adhering to local environmental regulations.

Within procurement, the process is complete when the product or service the buyer has been tasked to source and buy has been delivered, checked, and paid for. At this point, the immediate responsibility of the procurement team often concludes. For further insights into specific procurement processes, explore our guide on Supplier Relationship Management.

Supply Chain Management: The Holistic Journey

In contrast to procurement’s focused scope, supply chain management takes a much broader, end-to-end view. The fundamental distinction between Procurement vs. Supply Chain lies in the duration of their processes: the process of supply chain management continues until the end product reaches the consumer. The role of procurement, as we’ve seen, might have ended long before this stage.

Let’s revisit our textile manufacturer. While procurement secured the raw materials, supply chain management oversees the entire flow:

- Supplier Relationship Management: This goes beyond just buying. It involves building long-term, strategic relationships with key suppliers to foster collaboration and ensure consistent quality and availability. For instance, working closely with a specific cotton gin to ensure fair trade practices and sustainable sourcing.

- Production Planning and Control: Optimizing the manufacturing process to ensure efficient use of resources and timely production. This could involve forecasting demand for certain fabric types and adjusting production schedules accordingly.

- Logistics and Transportation: Managing the movement of goods, both raw materials and finished products, across various locations. This includes selecting the right transportation modes (road, rail, sea), optimizing routes, and managing freight costs. Imagine coordinating trucks to transport finished fabric from Faisalabad to ports in Karachi for export, or to distribution centers across Pakistan.

- Warehousing and Inventory Management (Beyond Procurement’s Scope): While procurement handles initial stock control, supply chain management manages the flow of inventory throughout the entire network, from raw materials to work-in-progress to finished goods, across multiple warehouses and distribution centers. This ensures products are available where and when needed, minimizing storage costs and avoiding obsolescence.

- Distribution and Retail: Getting the finished product into the hands of the consumer, whether through retail stores, e-commerce platforms, or other channels. This involves managing relationships with distributors and retailers, ensuring efficient order fulfillment, and potentially handling returns.

- Customer Service: Ensuring customer satisfaction throughout the product’s journey and beyond, including after-sales support and handling feedback.

The fundamental distinction between Procurement vs. Supply Chain lies in the duration of their processes: the process of supply chain management continues until the end product reaches the consumer. The role of procurement, as we’ve seen, might have ended long before this stage.

The Interdependence: Procurement as the Lifeblood of the Supply Chain

While distinct, it’s crucial to understand that supply chain management and procurement are deeply interdependent. Procurement is the engine that feeds the entire supply chain. Without efficient and effective procurement, the supply chain would grind to a halt due to a lack of necessary inputs. Conversely, a well-managed supply chain ensures that the value created through strategic procurement is realized by delivering products and services efficiently to the end consumer. The synergy between Procurement vs. Supply Chain is undeniable.

Think of Pakistan’s thriving e-commerce sector. Platforms like Daraz rely heavily on both. Their procurement teams are constantly sourcing products from various vendors, from small businesses in remote villages selling handicrafts to large electronics distributors. Their supply chain management then takes over, handling everything from warehousing these products, managing logistics partners like Leopards Courier and TCS, to ensuring timely delivery to customers across the country. A breakdown in procurement (e.g., failing to secure popular items) or in supply chain management (e.g., delayed deliveries) can significantly impact their business. For more on logistics, you might find this article on Logistics Management Best Practices insightful.

In Conclusion: A Synergistic Relationship for Pakistani Businesses

In essence, procurement is a vital component, a foundational function that ensures an organization acquires what it needs. Supply chain management, on the other hand, is the overarching framework that orchestrates the entire flow of goods and services, from their origin to their final destination, optimizing efficiency and customer satisfaction. Understanding this critical distinction between Procurement vs. Supply Chain allows businesses in Pakistan and globally to strategically manage their resources, mitigate risks, and ultimately achieve greater success in an increasingly competitive marketplace. At ProcureXpert.net, we are committed to providing insights that empower your journey through the complexities of procurement and supply chain excellence.